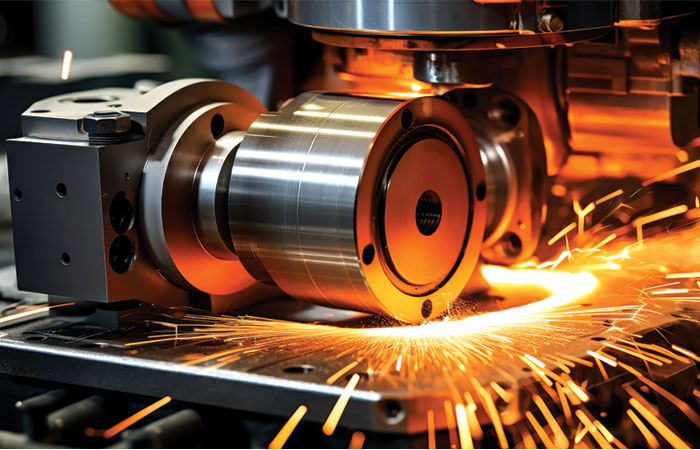

The realm of advanced manufacturing has witnessed significant technological advancements, with mill-turn technologies standing out as a pivotal innovation. These multi-functional machines combine the capabilities of milling and turning, enabling manufacturers to produce complex parts with high precision and efficiency. This article delves into the core aspects of mill-turn technologies, their benefits, applications, and future potential.

Understanding Mill-Turn Technologies

Mill-turn machines integrate the functionalities of CNC milling and CNC turning into a single setup. This combination allows for the execution of multiple machining operations without the need to transfer parts between different machines. Typically, a mill-turn machine includes:

- Rotating Spindles: These facilitate turning operations, allowing the workpiece to be rotated at various speeds.

- Milling Spindles: These are used for cutting, drilling, and other milling operations.

- Multi-Axis Movement: Advanced mill-turn machines often feature multi-axis capabilities (e.g., 5-axis or even 9-axis), enabling intricate and complex machining.

Benefits of Mill-Turn Technologies

- Enhanced Precision: By consolidating multiple operations into a single setup, mill-turn machines reduce the cumulative error that can arise from transferring workpieces between different machines. This consolidation ensures higher accuracy and consistency in the final product.

- Increased Productivity: The integration of milling and turning operations streamlines the manufacturing process. It reduces setup times and minimizes workpiece handling, leading to faster production cycles and higher throughput.

- Reduced Labor Costs: With fewer setups and less manual intervention required, mill-turn technologies can significantly reduce labor costs. Operators can manage multiple machines simultaneously, further enhancing productivity.

- Space Efficiency: Combining milling and turning into one machine saves valuable floor space, which is particularly beneficial in high-cost manufacturing environments.

- Complex Geometry Handling: Mill-turn machines are adept at producing parts with complex geometries and tight tolerances, making them ideal for industries that require high precision, such as aerospace, automotive, and medical devices.

Applications

- Aerospace: The aerospace industry demands components with intricate shapes and tight tolerances. Mill-turn machines are capable of producing turbine blades, engine components, and other critical parts with the required precision and reliability.

- Automotive: In the automotive sector, mill-turn technologies are used to manufacture engine parts, transmission components, and other complex mechanical systems. The ability to produce high-precision parts efficiently is crucial in this competitive industry.

- Medical Devices: The medical industry requires components with extremely high precision and often with complex shapes. Mill-turn machines are used to manufacture surgical instruments, implants, and other critical medical devices.

- Oil and Gas: For the oil and gas industry, mill-turn technologies are used to produce valves, fittings, and other components that must withstand high pressures and harsh environments.

Future Trends

The future of mill-turn technologies is marked by continuous advancements aimed at further enhancing precision and productivity. Some of the emerging trends include:

- Automation and Robotics: Integration of automated loading and unloading systems, as well as robotic arms, will further reduce manual intervention and increase production efficiency.

- Digital Twin Technology: Implementing digital twins allows for real-time simulation and monitoring of the machining process, ensuring optimal performance and predictive maintenance.

- Advanced Materials: As new materials with superior properties are developed, mill-turn machines are being adapted to handle these advanced materials, expanding their application scope.

- AI and Machine Learning: Incorporating AI and machine learning can optimize machining parameters in real-time, leading to improved quality and reduced cycle times.

Mill-turn technologies represent a significant leap forward in the manufacturing industry, offering unparalleled precision, productivity, and versatility. As these technologies continue to evolve, they will undoubtedly play a crucial role in shaping the future of advanced manufacturing. For industries that demand high precision and efficiency, investing in mill-turn technologies is a strategic move towards achieving greater competitiveness and innovation.

Mill-Turn Equipment

Mill-turn machines are sophisticated pieces of equipment that combine the capabilities of CNC milling and CNC turning into a single setup. These machines are designed to perform a wide range of machining operations, making them essential for high-precision and high-productivity manufacturing. Here, we highlight the key features and components of mill-turn equipment:

Key Components

Rotating Spindle (Main Spindle):

Function: Central to the turning operation, the main spindle holds and rotates the workpiece.

Features:

- High-speed rotation for efficient turning.

- Precision bearings to ensure stability and accuracy.

- Capable of accommodating a variety of chuck sizes and collets.

Milling Spindle:

Function: Performs milling operations such as cutting, drilling, and tapping.

Features:

- High torque and speed for efficient material removal.

- Swiveling capability for multi-axis milling.

- Tool magazine or turret with automatic tool changers for quick switching between tools.

Multi-Axis Configuration:

Function: Provides movement along multiple axes for complex machining operations.

Features:

- Common configurations include 3-axis, 5-axis, and even up to 9-axis machines.

- Advanced kinematics to handle intricate geometries.

- Simultaneous multi-axis control for high precision.

Bed and Frame:

Function: Provides the structural foundation and stability for the machine.

Features:

- Constructed from high-strength materials to minimize vibrations.

- Rigid design to support heavy workpieces and high-speed operations.

Control System:

Function: Manages the machine operations and movements.

Features:

- CNC (Computer Numerical Control) systems with user-friendly interfaces.

- Real-time monitoring and adjustments for precision control.

- Integration with CAD/CAM software for seamless design-to-manufacturing workflows.

Tool Magazine/Turret:

Function: Stores and automatically changes tools during the machining process.

Features:

- High capacity for a wide variety of tools.

- Rapid tool change mechanism to minimize downtime.

- Intelligent tool management system to track tool wear and usage.

Tailstock/Sub-Spindle:

Function: Provides additional support for longer workpieces and secondary operations.

Features:

- Programmable movement for precise positioning.

- Can be equipped with a secondary chuck for additional turning operations.

- Enhances the machine’s versatility and ability to handle complex parts.

Coolant System:

Function: Delivers coolant to the cutting area to reduce heat and wear on tools.

Features:

- High-pressure pumps for effective coolant delivery.

- Multiple nozzles to ensure thorough coverage.

- Filtration system to remove chips and contaminants from the coolant.

Salient Features

- Integrated Machining Capabilities:

- Combines milling and turning operations in one setup, reducing the need for multiple machines and setups.

- Enables complex parts to be machined in a single operation, improving accuracy and efficiency.

High Precision and Accuracy:

Advanced control systems and precision components ensure tight tolerances and high-quality finishes.

Multi-axis capabilities allow for intricate and detailed machining.

Versatility:

Suitable for a wide range of materials, including metals, composites, and plastics.

Can handle a variety of part sizes and complexities, making it ideal for diverse applications.

Automation and Efficiency:

Automated tool changers and robotic systems for loading/unloading workpieces reduce manual intervention.

Streamlined operations lead to shorter cycle times and higher throughput.

Enhanced Productivity:

By consolidating multiple machining processes, mill-turn machines significantly increase production efficiency.

Reduced setup and handling times translate into faster overall production.

User-Friendly Interfaces:

Modern CNC control systems feature intuitive interfaces that simplify programming and operation.

Advanced simulation and monitoring tools help operators optimize the machining process.

Conclusion

Mill-turn equipment represents a pinnacle of modern machining technology, offering unparalleled precision, versatility, and efficiency. With their ability to integrate multiple machining processes into a single setup, these machines are invaluable assets in industries that demand high precision and productivity. Investing in mill-turn technologies can lead to significant improvements in manufacturing capabilities, making them a cornerstone of advanced manufacturing strategies.