As per a recently published research report1, India’s electric vehicle (EV) market size is expected to reach USD 152.21 billion by 2030.

While the industry is at a nascent stage, EVs are gaining traction in the country, owing to more stringent regulations around vehicular emissions, increasing environmental concerns, encouraging government subsidies and significant technological advances.

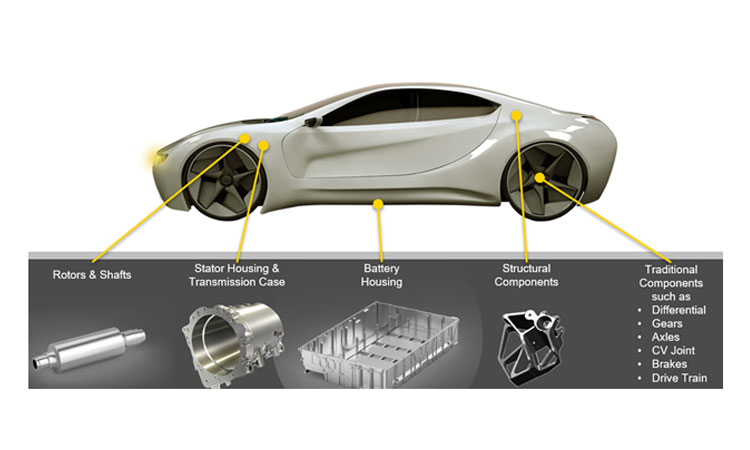

As automotive manufacturers expand their hybrid and electric vehicle offerings, Kennametal is innovating to meet growing customer demand for EV machining solutions. The figure below shows the many key components in a typical electric passenger vehicle that need precision machining:

One way Kennametal is innovating for the EV market is by leveraging the design flexibility of additive manufacturing. Our innovative 3D-printed stator bore tool weighs half that of the conventionally manufactured version, while still meeting accuracy, roundness, and surface finish requirements for aluminum motor body boring. This technology, combined with a carbon-fiber-body and our proven RIQ inserts technology enables high productivity and reliability in the production of large diameter, deep bore electric motor housings.

“By leveraging advanced manufacturing techniques like 3D printing, we’ve reduced weight a further 20 percent over the first-generation tool, while improving chip control and increasing tool rigidity—innovations that help our customers machine faster and more efficiently,” says Ingo Grillenberger, Product Manager, Kennametal.

This newly redesigned tool recently won MM MaschinenMarkt’s Best of Industry Award in the Production and Manufacturing category based on votes by readers and industry experts.

In addition to innovative metal cutting tools for the conventional structural parts and drive train components like gears, axles, CV joints, brake assemblies and drive systems, we provide complete comprehensive machining solutions, both with standard and custom tooling for various EV components like:

Rotors and shafts

These are subject to bending and/or twisting and require high surface hardness values along with good core toughness, excellent machinability in soft condition, suitable for direct hardening. Kennametal offers cutting tools for each of these operations that optimize Cost Per Part (CPP) through features such as high chip removal rate, flexible geometries, multitasking capabilities, and excellent lifecycle cost.

Stator housing and transmission cases

Built from aluminum alloys, and occasionally steel for the bearing seat, these require operations to profile large diameters with IT 6 tolerance, while retaining geometric tolerances such as co-axiality and concentricity between the main bore, bearing seat and case cover diameter. Kennametal has introduced advanced solutions such as HPS drills, Face Mills, and PCD- Solid Carbide End Mills for special milling operations and application-oriented custom solutions that are ideal for this component. Their features include lightweight design of tools, options for manual as well as automatic tool changer handling, tilting moment, vibration avoidance, optimum moment of inertia (acceleration / deceleration time and power consumption of machine), reduced wear of machine components and optimized coolant flow and adjustable tool to handle temperature expansion.

Differential housing

Most electric vehicles will have one main electric motor. The drive from this motor must therefore be distributed to the wheels via a differential in the drive axle, just as with an engine-driven vehicle. In the case of 4WD cars, each wheel can be fitted with an electric motor (electric differential) although it largely depends on the type of drive system. These components are made up of aluminum alloys or cast iron and require intricate internal operations with difficult accessibility. Kennametal offers modular drilling tools, where a low quantity of different inserts is required along with KM50 internal sphere unit for components requiring mass production, highly specific process, and programming capabilities.

Battery housing

Batteries, being at the heart of EVs, require robust yet lightweight housing to ensure smooth functioning. Typically used materials are Aluminum Casting Alloys (e.g., AlSi10MnMg), Aluminum Extrusion Profiles (e.g., AlMgSi1, AlMgSi0,7), while some of the new age materials include composite materials (e.g., CFRP) and sheet steel. Aluminum material with low silicon content typically gives long chips and is more susceptible to built-up edges. There is also risk of vibration as well as deformation and bending due to extremely thin wall thicknesses and occurrence of delamination in composite materials. Composite machining requirement for battery housing can be done with the compression-style end milling router that generates cutting forces into the top and bottom surfaces of the workpiece. The design of these tools is so unique that it helps to stabilize the cutting forces while in cut and thus prevents damage to the workpiece edges.

As the transportation industry keeps evolving, Kennametal is developing innovative tooling solutions for our customers across the mobility ecosystem—be it for EVs, Hybrids or ICEs.