There are two different ways of using sensors in the field of hydraulics. It is possible to integrate the sensors if it is already known during design that a sensor is required for displacement measurement, or later, if this requirement is only recognised in hindsight. Both approaches are basically different from the viewpoint of the measurement technology.

Integrated sensors

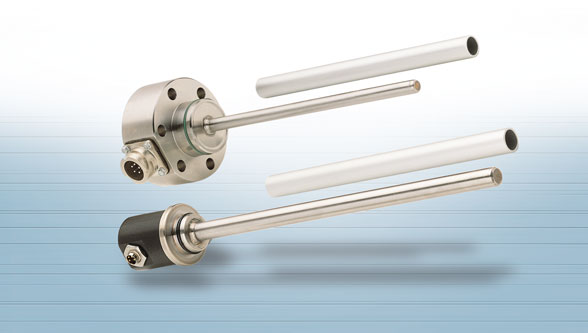

If it is already certain during the design phase that displacement measurement is required, it makes sense to install the sensor in a compact as possible design envelope. Ideally, the sensor is directly integrated into the hydraulic cylinder and designed as an elementary component (cylinder cover). induSENSOR eddy current long-stroke sensors from the Micro-Epsilon EDS series are used for these types of applications. The measuring principle is based on the eddy current effect. The sensor elements of this series are protected by a pressure-resistant stainless steel housing. Controller and signal processing are completely integrated into the sensor flange. As a target, an aluminium sleeve is used, which is integrated into the piston rod and is passed over the sensor rod in a non-contact, wear-free manner.

Measuring principle

If the compensating and the measuring coils are supplied with an alternating current, two orthogonal magnetic fields are produced in the tube. The field produced from the single-layer measuring coil has a magnetic coupling with the target. Therefore, the eddy currents produced in the target form a magnetic field, which influences the impedance of the measuring coil. This changes linearly with the position of the target. The electronic circuit forms a signal from the relationship of the impedances of both coils and converts to piston position to a linear output signal. In doing so, the temperature influences and the temperature gradient are eliminated. Due to the eddy current effect principle used, there does not have to be any permanent magnets installed inside the cylinder, which is why the sensor is extremely resistant to external electromagnetic influences. On account of its robust design, this sensor system has also proven itself in harsh industrial environments, as well as the integration in hydraulic and pneumatic cylinders.

Inductive displacement sensors provide more precision

For decades, Micro-Epsilon has been renowned for its inductive displacement sensors and gauges and has extended the range of classical measurement techniques such as LVDT (Linear Variable Differential Transformer) by further innovative developments. This designation describes a method of inductive displacement measurement in which the primary windings are supplied with a constant alternating voltage. The primary windings produce an alternating field, inducing a signal in the secondary coils, the strength of which depends on the core position. induSENSOR displacement sensors from Micro-Epsilon are used extensively in applications for automated processes, quality assurance, test rigs, hydraulics, pneumatic cylinders, and automotive engineering.

The advantages of these displacement sensors are well known and highly valued, and include ruggedness, reliability under harsh conditions, high signal quality and good temperature stability. The sensors are used successfully both in single and high volume OEM applications, where often customer-specific requirements must be implemented.

Applications in detail

Eddy current long-stroke sensors are amongst others used in railway engineering. When taking a bend, the coach body on the vehicle is tilted towards the inside of the bend with the help of hydraulic cylinders. The degree of tilt is acquired by an EDS sensor. This means the trains can travel faster around curves in the track and time is saved.

Typical applications in the automotive industry include the deflection of hydraulic suspension in commercial vehicles, positioning of convertible top cylinders, as well as pedal and clutch displacements. In heavy industries, these precision sensors measure and regulate the grinding gap of crushers.

Retrofitting

Retrofitting a displacement measurement system occurs almost as often as the method of already integrated sensors. If there had initially been no need for a displacement measurement system, it was not possible to integrate the cylinder at a later time. However, there is now an alternative solution. The displacement measuring system is attached to the outside in the same axis as the cylinder. Draw-wire sensors are often used for this on account of their robust design, easy handling and extremely favourable unit price. They measure linear movements using a highly flexible steel wire. The wire is wound on a drum, whose axis is coupled with a potentiometer or encoder. The end of the wire is attached to the measuring object. A rotating movement of the drum is produced when a change in the distance of the measuring object from the sensor occurs. This rotating movement is converted to an electrical signal and output using an encoder or potentiometer.

Application examples for retrofitted displacement measurement systems

A typical example of retrofitting is the mounting of the sensor on the supports of elevating work platforms or truck-mounted cranes. Cranes often have to move heavy loads in their working range, which can be up to 100 metres. Due to this wide lift distance, fixed limits are specified for the permitted load torque, which is defined by the load capacity and the length of the boom. These limits must be complied with in order to guarantee the safety of the crane. For this reason, truck-mounted cranes have lateral supports, which extend the footprint of the crane. If possible, these supports are fully extended in order to use the maximum footprint. However, in some situations, for space reasons it is not possible to fully extend the supports, whereby the permitted load capacity of the telescopic boom is unexpectedly reduced. In such situations, up to now it has not been possible for a crane operator to operate the crane, as this only functioned with fully extended supports for safety reasons. It is a legal requirement that operation of the crane with load torque limitation. A well-known German manufacturer of truck-mounted cranes installs draw-wire sensors from Micro-Epsilon as standard for its working platforms, in order to make working possible in confined spaces. There are two sensors on each support. The sensors notify the crane controller how far the support has been extended. The maximum permitted load torque is determined using other measured values, such as the hoist capacity and the length of the boom. The crane only lifts the load if the permitted limit values are complied with. This rules out that the crane will tip over due to overloading of the boom when the supports are not fully extended.

Solutions to any problem

In harsh environments in which cylinders are frequently used, the draw-wire sensor can only be used with caution as dirt and mechanical loads may destroy the sensor over the long term. This limitation also applies when using optical or magnetic measuring rods. Here, the measuring rod is also installed on the outside of the cylinder. A grid applied to the bar is scanned optically or inductively. As this sensor is also outside on the cylinder, it is susceptible to soiling. Due to these limitations, the two companies Sensor-Technik Wiedemann from Kaufbeuren and Micro-Epsilon from Ortenburg have developed an alternative solution. Both companies have many years of experience in the field of sensor systems. The co-developed solution is based on the draw-wire sensor, which is integrated inside the cylinder. Here, the sensor is completely protected from external influences.

In harsh environments in which cylinders are frequently used, the draw-wire sensor can only be used with caution as dirt and mechanical loads may destroy the sensor over the long term. This limitation also applies when using optical or magnetic measuring rods. Here, the measuring rod is also installed on the outside of the cylinder. A grid applied to the bar is scanned optically or inductively. As this sensor is also outside on the cylinder, it is susceptible to soiling. Due to these limitations, the two companies Sensor-Technik Wiedemann from Kaufbeuren and Micro-Epsilon from Ortenburg have developed an alternative solution. Both companies have many years of experience in the field of sensor systems. The co-developed solution is based on the draw-wire sensor, which is integrated inside the cylinder. Here, the sensor is completely protected from external influences.

The sensor is positioned at the bottom of the cylinder and the measuring wire is attached to the bottom of the piston. A particular challenge here is the design of the sensor and the signal routing to the outside, as a bore hole in the cylinder housing is always a weak point. With pressures of up to 600bar in the cylinder, leakage is a risk that must be prevented. As well as the housing, the essential elements of a conventional draw-wire sensor are the spring, the drum, the measuring wire and a protractor as sensor element. A housing for the sensor can be dispensed with in this application, as the cylinder takes over this function. Each movement of the piston causes a rotation of the wire drum. The rotation movement is divided using a gearbox onto two shafts with different rotation speeds. A magnet is positioned on each shaft at the bottom of the cylinder, whose positions can be measured by external, magnetic angle sensors. Using a suitable gearbox, each combination of the magnet positions only occurs once across the complete measuring range. The sensor therefore shows the characteristics of an absolute encoder.

Author:

Dipl.-Ing. Thomas Birchinger

MICRO-EPSILON MESSTECHNIK

GmbH & Co. KG

Website: www.micro-epsilon.com