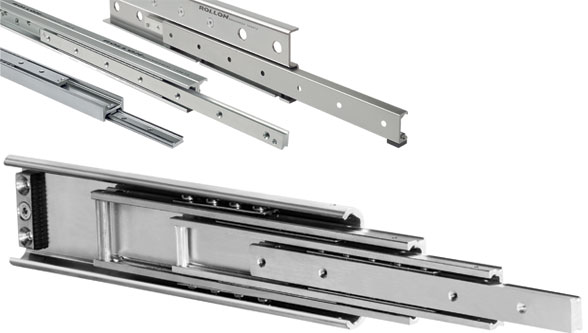

The telescopic bearings from Rollon deliver high load capacity and rigidity for applications in harsh industrial environments. If your application requires one, there are some things you’ll want to consider like material and stroke options, load placement and life calculation. Here are some pointers to help you pick the right bearing for your application

Rollon offers a wide range of telescopic guides with high rigidity, high load capacity, 200% extension and several accessories available. The new Hegra Rail family of telescopic guides includes guides with an extended length up to 200% greater than the closed length (overextension). The telescopic guides produced by Rollon are available with several accessories like locking systems, snaps or damping systems.

Materials

To minimize deflection, carefully consider all possible materials for your telescopic bearing. Some common materials, along with their pros and cons, include:

- Aluminum: Even though it’s a good choice for lightweight and low duty applications, aluminum has more deflection than other materials. Rollon related products: Hegra Rail

- Stamped Steel: Easily the most economical choice, stamped steel doesn’t handle vibration and shock loads as well as other materials. Rollon related products: Light Rail

- Cold Rolled Steel: Cold rolled steel is another low cost option that doesn’t undergo heat-treatment. However, in case of heavy loads, pitting and denting occurs in raceways since the ball hardness is greater than the rail and slider.Rollon related products: Opti Rail, Hegra Rail

- Hardened Cold Rolled Steel: For the most robust designs, hardened cold rolled sliders and raceways are your best bet. Even though they’re most expensive to manufacture and assemble, this material lets you preload for better rigidity and less deflection.Rollon related products: Telescopic Rail.

Stroke Options

When picking a telescopic bearing, there are three stroke options to choose from: partial, full and over-extension. Partial extension stroke refers to an extension length that’s 50 to 65% less than the closed length.>

Rollon related products: ASN, LPS

In a full extension stroke, the extended length is equal to the closed length. Rollon related products: DE, DS, DSC, DBN, DMS, DRT, LTH, LTF, LFS, LFX, DRX/DRS

With over-extension, the extended length is up to 200% greater than the closed length. Rollon related products: DSE, H2D, H2C, H2T

Telescopic rails also come with dual or double stroke configurations, allowing loads to move in both directions while maintaining the same closed length.

Load Placement

Another important factor to consider is load placement. Your load’s center of gravity should be placed as close as possible to the centre of the moving element for even load distribution among the balls. Load calculations are usually made with the assumption that the load is properly distributed.

When calculating the static load a safety factor S has to be used, it takes into account the basic parameters of the application and it can have a value between 1 and 3,5 in the following formula:

Where P is the effective load, C the permissible load and S the safety factor.

Life Calculation

When sizing a telescoping bearing for continuous operation, make sure you use the right life calculation and dynamic load capacity. Some manufacturers express load and deflection specifications based on the slides being used in pairs, while others think of load capacity using a single rail. You should take the time to understand how the slides are rated and what specifications the manufacturer provides.

The service life of a telescopic rail is dependent on several factors, such as the effective load, the installation precision, occurring shocks and vibrations, the operating temperature, the ambient conditions and the lubrication.

The service life can be calculated with the following formula:

Lkm = calculated service life in km

δ = load capacity factor in N

W = equivalent load in N

fi = application coefficient