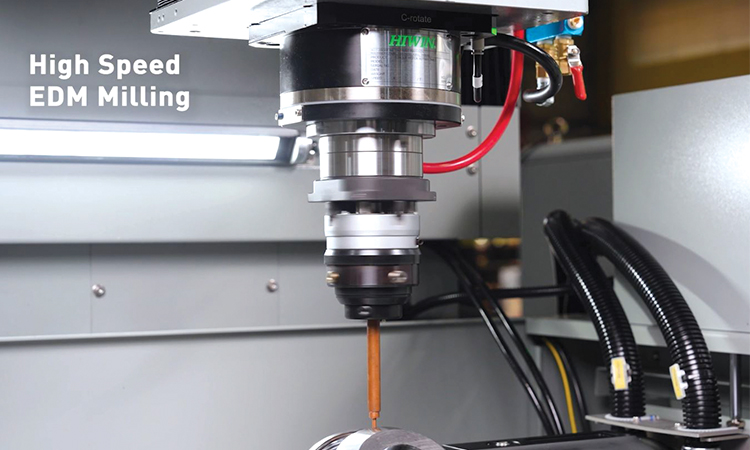

As India’s manufacturing sector advances toward precision, efficiency, and sustainability—especially in aerospace, semiconductor, and automotive industries—EDM technologies are evolving to meet these demands. HIWIN’s high-speed EDM milling head RCH-100E introduces a breakthrough in machining performance, combining direct-drive innovation, intelligent diagnostics, and eco-conscious design to set a new benchmark in advanced manufacturing.

HIWIN High-Speed EDM Milling Head (RCH-100E) with Direct Drive design, is used in high precision application & produce parts for aircraft, semiconductor & automotive industries.

• Innovative Value: Integrated with torque motor, RCH-100E with precise indexing 0.0005° & high rotation speed 300 rpm, 3 times higher than mechanical type, with 15 times improvement & continuous operation advantage.

• Process Technology: Traditional EDM’s electrode runs vertical movement to remove material. RCH-100E’s New “EDM milling” Technology, increases efficiency 5 times with 2 um accuracy.

• Smart Diagnostic: Integrated leakage, temperature sensor systems with “intelligent detection” to provide conditions feedback & enable users to plan maintenance.

• Energy-saving and Carbon Reduction: Utilize special aluminum alloy to reduce 30% weight maintaining same rigidity. EDM milling technology reduces copper electrodes consumption by 70% thus reducing production costs.

Performance Advantages: Speed, Efficiency, and Accuracy

HIWIN’s high-speed EDM milling head RCH-100E is equipped with a self-developed direct-drive high-speed motor, increasing the spindle speed by 15 times. Its structure, made with a special alloy material, reduces weight by 30%, offering the industry a high-performance, energy-saving, and carbon-reducing solution. Through the application of EDM milling technology, it significantly improves processing efficiency.

Using the HIWIN RCH-100E can increase productivity by 5 times within the same operating time and reduce copper electrode consumption by 70% during the EDM process. These features not only deliver energy savings and high efficiency but also help minimize material waste.

Sustainability in Design: Lifecycle and Recycling Focus

90% of the components in HIWIN’s high-speed EDM milling head RCH-100E are made in-house by HIWIN, with most parts using aluminum alloy materials. This gives HIWIN the flexibility to redesign and upgrade existing rotary tables, extending their lifecycle through refurbishment or restoration.

When a rotary table reaches the end of its service life, its components can be recycled, melted down, and re-cast to manufacture new products or assemblies, reducing the demand for natural resources and minimizing environmental impact. Key internal components such as the torque motor can also be disassembled for recycling—its metal casing, copper wiring, and iron core can all be reused, effectively reducing waste generation.

For more information,

www.hiwin.tw