Understanding the behaviour of metals, alloys, and coatings under real-world operating conditions is critical for designing durable mechanical assemblies. The performance and service life of such components largely depend on their resistance to wear, friction, and corrosion. Traditionally, industries rely on multiple high-cost instruments to study these parameters, each providing fragmented data that requires extensive analysis to correlate.

To address this challenge, Surface Modification Technologies Pvt. Ltd. (SMTPL) has developed an innovative Tribo-Simulator, a compact and cost-effective machine that integrates coating thickness measurement, wear rate analysis, and friction coefficient evaluation into a single, user-friendly platform.

From Calo-Tester to Tribo-Simulator – The Evolution of an Idea

The concept of the Tribo-Simulator originated from the well-known Calo-tester, a standard instrument used in the coating industry for measuring coating thickness through a controlled abrasion method.

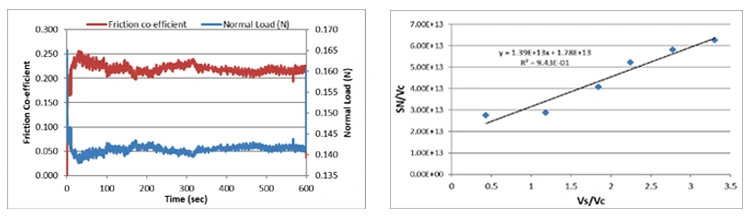

At SMTPL, our scientists extended this concept by integrating advanced physics-based models of wear and friction, including KVH model for wear coefficient and Rutherford’s model for friction coefficient, into a single experimental framework. The result is an intelligent and versatile machine capable of providing a comprehensive understanding of coating and substrate interactions under simulated working conditions.

Unlike traditional wear testing systems, the Tribo-Simulator bridges the gap between laboratory characterisation and real-life component performance, enabling users to derive practical, predictive insights that are directly applicable to industrial design and material optimisation.

Key Features and Capabilities

The Tribo-Simulator is designed to characterise the following parameters within one experimental setup:

- Coating Thickness / Nitriding Case depth Measurement

- Coating Wear Rate

- Substrate Wear Rate

- Combined Coating and Substrate Wear Rate

- Friction Coefficient between Mating Surfaces

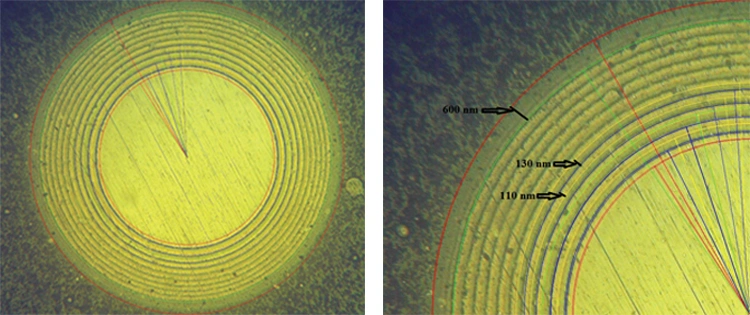

Through a precisely controlled wear process, the instrument generates a wear crater on the coated or uncoated specimen. The resulting wear scar (crater) is analysed to extract both quantitative and qualitative information, reflecting the true wear and frictional behaviour of materials used in industrial components such as bearings, gears, dies, valves, cutting tools and various industrial components.

The system allows users to simulate real operating conditions, such as load, speed, pressure, and contact geometry, and evaluate the corresponding material response within a short test cycle.

Advantages over Conventional Systems

Compared to existing tribological instruments available globally, the SMTPL Tribo-Simulator offers distinct advantages:

- Cost-Effective: Significantly lower cost compared to conventional tribometers or nano-wear testers.

- Simple and Versatile Operation: Can be operated even by non-specialist personnel.

- Compact and Flexible Design: Suitable for both research laboratories and industrial environments.

- Rapid Results: Generates predictive data in hours instead of days or weeks.

- Integrated Analysis: Correlates wear, friction, and material degradation in a single test.

This makes the Tribo-Simulator an ideal tool for industrial R&D centres, surface engineering labs, and material development teams seeking fast, reliable, and affordable testing solutions.

Industrial Impact and Customer Experience

The Tribo-Simulator has already been deployed across select industrial facilities for validation and application studies. The feedback has been highly encouraging, with users reporting faster material screening, improved understanding of coating and surface performance, and better optimisation of process parameters.

A leading automotive component manufacturer shared:

“Delighted to acknowledge the contribution of TRIBO-Simulator DCK-1 (Formerly Calotester) in the strengthening of our testing lab capability. With the help of the said equipment, we are able to simulate the wear properties of the coatings in a very precise and reliable way. So thanks for the contribution in our study by suggesting the Tribo-simulator.

We look forward to keep a good association for our future requirements.”

Applications Across Industries

The versatility of the Tribo-Simulator extends far beyond PVD or CVD coating characterisation. It is equally effective for studying:

- Surface and Subsurface Treatment Processes such as nitriding, carburising, hard anodising, laser surface modification, shot peening, and thermal treatments.

- Bare Metals and Alloys, allowing engineers to assess inherent wear and frictional characteristics before any surface modification.

- Treated and Coated Materials, enabling direct comparison of performance before & after treatment.

- R&D on Novel Materials for automotive, aerospace, energy, biomedical, and precision engineering applications.

In essence, the Tribo-Simulator acts as a universal platform to study how any surface treated, coated, or bare responds under controlled mechanical interaction, offering valuable insights into material behaviour and performance prediction.

Conclusion

The development of the Tribo-Simulator underscores SMTPL’s commitment to innovative applied research in surface engineering and material science. By combining simplicity, affordability, and scientific rigour, this indigenous machine enables industries to evaluate material behaviour quickly and cost-effectively, supporting the broader vision of “Make in India” for advanced testing and characterisation technologies.

The Tribo-Simulator stands as a symbol of Indian innovation in tribology, empowering industries and researchers alike to better understand, predict, and enhance material performance under real-world conditions.

About the Author:

Dr. Umesh Mhatre

Managing Director

Surface Modification Technologies Pvt. Ltd. (India)