Global engineering company Renishaw returns to Formnext in 2018 to showcase that it is possible to significantly increase additive manufacturing (AM) productivity without compromising on quality. Since the launch of its four-laser RenAM 500Q system, Renishaw has developed extensive expertise in multi-laser applications in AM and established a deep understanding of how lasers interact with each other and the part. From the 13th to the 16th November, Renishaw can be found in Hall 3.1, Stand E68 at Messe Frankfurt, Germany.

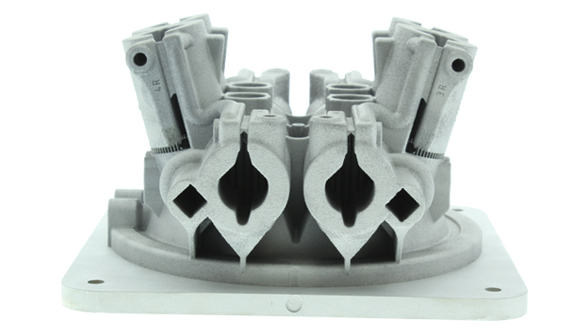

In 2017, Renishaw launched the RenAM 500Q, a pioneering four-laser system with precision dynamic focussing and a full-field view of the powder bed. This pioneering system transforms productivity in the most commonly used platform size, raising productivity and decreasing cost-per-part. Testing and analysis has now proven that multiple lasers can operate independently on separate parts or co-operate on a single, large component without diminishing the quality of the material produced.

Multi-laser additive manufacturing has opened up new product design opportunities for a range of industries as the technology becomes more accessible. Ensuring users have the freedom to unlock all the benefits of multiple lasers requires file preparation and simulation tools to allow that freedom to be exploited without compromising quality. Renishaw will also demonstrate the latest version of its QuantAM build preparation software, with laser assignment tools that empower users to develop processing strategies in line with the quality and productivity demands of their applications.

“When there are multiple lasers in close proximity, there is the potential that emissions from one laser could affect another,” explained Marc Saunders, Director of Global Solutions Centres at Renishaw. “This is dependent on their relative position within the machine’s inert gas flow. The first generation of multi-laser machines used zoning to avoid this issue, combined with either linear or divergent gas flow.

“However, this strategy has several drawbacks including reduced productivity for non-symmetrical builds, discontinuities as a result of thermal drift in the optical systems and varying melting conditions as a result of divergent gas flow,” added Saunders. “The design of Renishaw’s RenAM 500Q overcomes these drawbacks and enables efficient use of all four lasers. Renishaw is ensuring that its machine is as productive as possible, without any compromise on quality.”

As well as offering attractive benefits, Renishaw has completed extensive testing to understand the potential of interaction between the lasers. The machine boasts melt-pool and laser power monitoring capabilities to provide evidence of melting behaviour in real-time. Building on its knowledge, Renishaw has ensured its machine performance is consistent and can offer guidelines to enable customers to produce high-integrity components in a productive and flexible way.

At the show, Saunders is speaking on the TCT introducing stage on Tuesday November 13th from 11.30am to 11.45am. The session will cover how to radically improve productivity with multi-laser systems, without compromising on product quality.

For more information,

Website: www.renishaw.com