The SCHUNK VERO-S quick-change pallet modules offer a whole bundle of advantages for users when it comes to direct workpiece clamping without interfering contours: free 5-sided access to the workpiece, a defined clamping situation, high repeat and positioning accuracy, as well as high pull-down forces for challenging operations

SCHUNK further extends its modular system for workpiece direct clamping in order to ensure that the efficient principle will also work in the field of tool and mold making industries for free-form parts with complex geometries, small lot sizes, and high precision requirements.

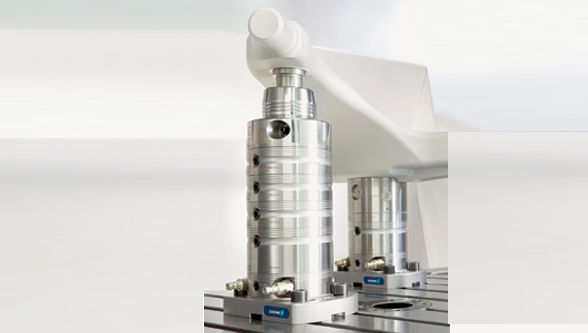

By using SCHUNK WDB basic modules, WDS staple modules, or WDN direct clamping modules (Ø 99 mm), which can be flexibly combined with the clamping pillars in various heights, the molding plates, free-form parts, and other workpieces can be directly clamped on the machine table in no time at all. No additional clamping devices are required, so there are no interfering contours. The compressed air supply of the direct clamping modules is ensured via media transfer. Monitoring of the workpiece presence is also possible. The clamping pillars ensure a defined clamping situation, a reliable simulation, and a collision-free, highly efficient operation. Due to the high accuracy of the clamping solution, workpiece changes can be implemented quickly. In addition, parts clamping can be done precisely and easily according to the existing retrofitting plan and the parts can be machined again.

Flexible components for free-form parts

Due to the modular nature of the product, custom solutions are not required. The new module sizes of the extended modular system from height 80 mm on are finely graduated in 10 mm steps and are easy to implement: The staple modules are available in five heights (30 mm, 50 mm, 80 mm, 120 mm, and 160 mm), and can be actuated with a hexagon key in no time at all. The force- and form-fit clamping connections lock the individual modules with pull-down forces of up to 25,000 N (at an actuation torque of 50 Nm). Thereby the integrated pull-down function ensures maximum hold, and in turn for maximum stability.

The direct clamping modules are available in three versions, that connect the clamping pillars with the workpiece: pneumatically actuated (6 bar) with a fixed Z-axis reference, and manually or pneumatically actuated with integrated compensating function in Z-direction (11 mm). The latter is used for deformation-free support of the workpieces. For system implementation the system on every common machine table, the modular system includes basic module versions for T-slot plates, grid plates, and VERO-S clamping stations. Standard fixed clamping pins without recess mount, cylindrical clamping pins, and conical clamping pin extensions are available as an interface to the workpiece. Special clamping pins with floating pitch compensation in one or two axes (each +/- 1mm) can be used for compensating workpiece tolerances or thermal expansion.

High accuracy

Every interface uses a scope-free taper centering, which ensures a repeat accuracy of < 0.005 mm. Feed chamfers at the module interfaces allow quick joining of the clamping pillars. The workpiece is clamped via spring force in a self-locking and form-fit fashion without needing compressed air. The workpieces remain safely clamped even in the case of a sudden pressure drop in the air system. In order to increase service life and process reliability, every functional part such as base body or clamping slide are made of hardened, stainless steel, are absolutely corrosion resistant and easy to clean.

For more information,

Website: www.schunk.com