Intralogistics is becoming more and more important in facilitating in-house processes at companies, and is also growing thanks to the constant increase in e-commerce. The degree of automation increases at the same rate as the need for personalized solutions, ranging from linear units, such as handling systems, to complete interlogistic systems. This may be followed by further development that can include collecting, packaging and palleting, often combined with wrapping machines.

Linear technology is the core business of our Italian company, with a branch in Bangalore, India. Its products cover a wide range of functions in relation to handling, like those that are part of intralogistics. The Rollon Group has maintained constant growth, increasing the number of orders, and developing new fields of application. In the last six months, it has acquired at least five manufacturers in the linear motion sector. These acquisitions are based on an important principle: they must be tailored to the company, with suitable integration of the product range and the Group’s capacity. For example, the acquisition of the Italian Company, TMT, in January 2017 was aimed at extending the range of self-supporting aluminum profiles. Integration of the range of products allows the linear technology experts to install light-weight “pick-and-place” Cartesian systems. In October 2017, the acquisition of the Italian company, T-Race, which specializes in linear and telescopic rails, followed the same principle: in fact, T-Race systems extend the choice of Rollon systems when it comes to intralogistics.

Expansion of production capacity for integrated solutions

In November 2017, the Limburg production plant that previously belonged to Hegra Linear moved to a new site. Expanding production capacity to 1800 square meters makes it possible to respond more quickly to customers’ needs and to increase production while reducing delivery times, implementing personalized solutions, and optimizing production processes. Rollon is also busy extending its Vimercate branch in Lombardy, where the production processes will be made more linear, with separation of production lines. The area set aside for actuators is combined in a new plant with a production area of 1800 square meters. Here too, there is an increase in capacity and a further reduction in delivery times. The aim of all the investments made is to offer the market the most extensive linear technology for intralogistics, and to enhance the product range with integrated solutions.

Rollon’s personalized intralogistic solutions

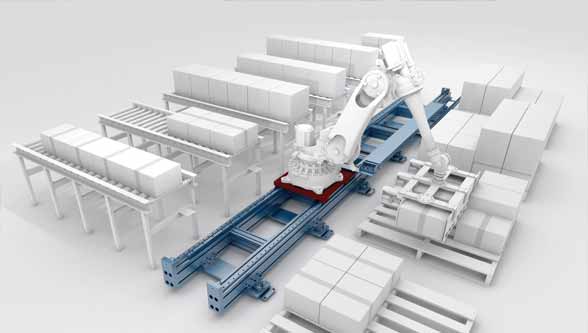

Starting from individual handling systems that carry out physical logistical processes such as handling, separating, collecting, packaging, and storing, our company designs and constructs complete handling and conveying lines, broken down for each area of application. Thanks to our wide range of high quality products, personalized intralogistic solutions can be put together more quickly and easily, and at lower costs than completely new systems which are designed from scratch. For example, when it comes to multi-axis portal systems, the designers are able to choose from various drive systems for the conveying units. Depending on its function, attention is focused on high dynamics, long strokes, moving heavy loads, or use under adverse ambient conditions. Shuttle systems, on the other hand, favor a high degree of rigidity, with the same dynamics. Overall, all applications have what the end client is looking for in terms of long-life and reliability.

You can find

Rollon India Pvt. Ltd. and its solutions for linear motion systems at:

PackPlus 2018

Hall 11 – Stand 11.42

July 25-28 New Delhi, India

Tailor-made intralogistic systems by Rollon are obtained by combining four product lines:

Linear Line: which includes linear and curved rails, with spheres or bearings, to carry out linear movements wherever necessary. The rails have high-strength, tempered sliding surfaces. There are systems suitable for use in demanding conditions, and other self-aligning systems when adaptation of tolerances is required.

Telescopic Line: includes telescopic rails with bearings or spheres, which Rollon makes in various construction forms and sizes, as well as special versions. The extractions can have tempered rails able to handle large loads with reduced bending. They resist impacts and wear, and can be extracted partially, totally or added to, and can be used for up to 200% of the sliding length.

Actuator Line: the linear axes, with various rail and drive configurations, are available with a belt, screw, or rack and pinion transmission, and are suitable for the widest range of needs, when it comes to precision, speed, and the rails used. They come with rollers or recirculating ball bearing systems, to meet the most diverse needs in terms of load and ambient conditions.

Actuator System Line: this is an evolution of the Actuator Line, and includes multi-axis systems for industrial automation. They are applied in numerous industrial systems: servo-systems for machines, high-precision assembly systems, packaging systems, and production lines with a high number of cycles and speeds.

Collecting, packaging, and palleting: some examples of intralogistic systems

Collecting, packaging, and palleting are important processes within the company, which often have to be combined with packaging machinery. Here, with its Actuator System Line, Linear Line, and Actuator Line systems, Rollon is able to put together turnkey mechanical systems that are highly dynamic, with limited bending of the linear units, even when dealing with large spans. The portal and gantry systems, along with Cartesian pick-and-place systems, combine high forces and torques, with precise positioning, which is standard for Rollon. Linear systems are highly durable, even in environments where abrasive dust is present and in conditions of continuous use.

Extraction mechanisms for horizontal and vertical storage systems

Rollon products are applied to horizontal and vertical shelving, vertical warehouses, and automatic warehouses for small parts, with personalized extraction systems suitable for large loads. Dynamics and large loads, along with limited bending, are guaranteed even for long strokes or high forces and torques. From large load warehouses to automated handling systems for medicinal products in pharmacies, all types of solutions are possible. The same applies to vertical systems and shuttle systems in refrigerated cells at 3°C, or at summer temperatures. Rollon has proved to be the ideal partner when it comes to modern intralogistic systems, thanks to its unload and stack systems that are easy to design using Linear Line rails, complex material flow and handling systems that involve the use of industrial robots, and the Actuator System line.

For more information:

ROLLON INDIA Pvt. Ltd.

Website: www.rollonindia.in