More Efficient Toolpaths with hyperMILL MAXX Machining

OPEN MIND Technologies AG produces the hyperMILL MAXX Machining performance package, a powerful tool for high-performance drilling, roughing, and finishing. These modules within hyperMILL feature special machining strategies that allow users maximum benefit from their machining centre and cutters. Two key enhancements have been added to the functional package: Perfect pocketing technology ensures extra efficient pocket machining with high-feed cutters. High-performance finishing and roughing strategies are also available with the package.

OPEN MIND has implemented a new high-performance mode for turning/roughing. This was made possible by applying the proven concept of trochoidal milling to turning. Optimized connecting paths and fluent machine movements ensure high-performance machining. The user benefits from the special plunge behavior of the insert in the material, which increases process reliability while reducing the manufacturing time.

Meanwhile, when it comes to finishing, OPEN MIND offers an innovative strategy to make optimal use of the special rollFEED inserts. The inserts’ large radii enable enormous time savings for finish turning.

Expanded range of functions for barrel cutters

Another new feature is the “5axis Prismatic Fillet Finishing” strategy, which supplements the innovative strategies for the highly efficient machining of planes and continuous surfaces. This strategy makes it possible to use barrel cutters according to the principle of high-feed cutters with plunging and pulling machining. The calculation of the optimal inclination of the barrel cutter is fully automated. This allows, among other things, high-quality transitions between different wall areas. This strategy perfectly complements the machining of deep pockets with barrel cutters.

Multi-surface machining

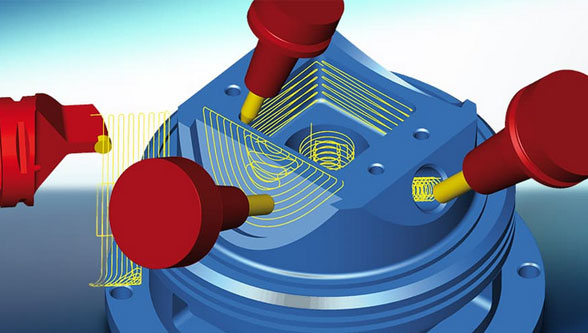

Multi-surface 5axis machining with conical barrel cutters makes it possible to produce entire surface formations in a single job. The toolpaths are generated fully automatically using a surface selection; this eliminates the time-consuming step of creating cutting contours in the CAD beforehand. As a result, high-quality surfaces can be easily programmed and quickly produced for both free-form surfaces and planes.

Mill pockets more quickly

To ensure maximum speed and efficiency, hyperMILL MAXX Machining also features perfect pocketing technology for roughing. An intelligent algorithm fits the largest possible pocket into the area to be roughed and automatically generates linear toolpaths for high feed milling. Linear and contour-parallel toolpaths are optimally linked to guarantee rapid production. Special retract movements reduce rest material in the corners.

Multifaceted applications for barrel cutters

hyperMILL offers a broad range of applications by supporting various barrel cutters. For example, a great deal of time can be saved by using barrel cutters during impeller or blisk production.

If the taper angle of the milling tool corresponds to the wall inclination, the barrel cutters can also be efficiently used for 3axis machining. All machining is always carried out in an efficient, collision-free way at the highest level of quality.