Have you unlocked the full potential of ANCA’s TapX grinding machine for tap production? ANCA continues to innovate with new features for the TapX, offering significant benefits for tap producers.

The TapX has proven successful in both high-value, quick-turn tap manufacturing and volume manufacturing. This single machine, with a single setup for tap production, offers a transformative solution.

Did you know the TapX allows you to fully control coolant pressure through Anca’s intuitive iTap software? Implementing coolant control improves production consistency and reduces costs.

The Importance of Coolant Pressure

Coolant pressure plays a key role in tap production. ANCA’s extensive experience in tap manufacturing has provided valuable insights into its importance. The TapX has always featured variable coolant control, but now, Anca has enhanced this with a new system that controls the coolant pump directly via a Variable Frequency Drive (VFD). This upgrade allows for efficient coolant use and reduces energy consumption, ultimately lowering production costs.

Tap Grinding Conditions

Tap grinding conditions differ from those of other tool and cutter grinding on ANCA machines:

- High-speed steel is the primary material for taps, with carbide material accounting for only about 1%.

- High-speed steel swarf behaves differently than carbide.

- Coolant is often heavily targeted at the grinding point to keep it clear of swarf and prevent burns during high material removal.

Using high-pressure coolant on smaller diameter tools or critical OD or finishing operations can cause unwanted variations. Controlling and reducing the pressure can mitigate these variations caused by vibration and deflection. Being able to control the coolant flow to adjust pressure as needed is ideal.

iTap Software Integration

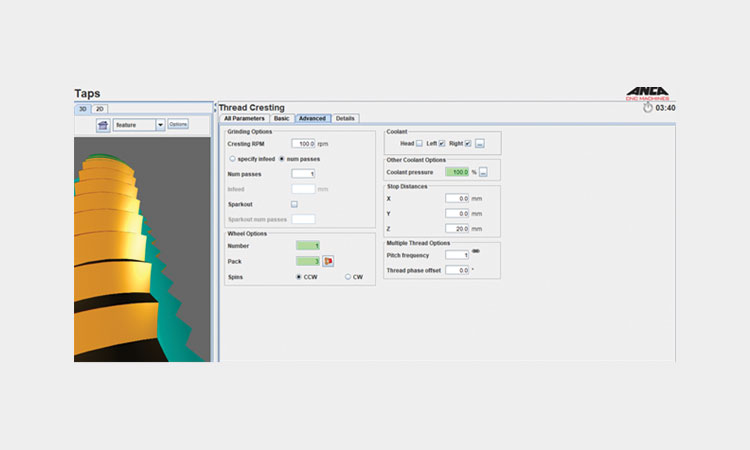

The TapX includes the iTap software package, which allows users to design taps easily and get up and running with minimal fuss. The iTap software includes coolant control for threading and cresting operations, making coolant management simple and accessible.

Note: A VFD must be fitted to the coolant pump.

Total Control in Tap Threading and Cresting

In tap threading, you can fully control the threading cycle. You can break down the threading operation into multiple passes, setting infeed, wheel speed, and coolant for each pass, giving manufacturers total control and flexibility. Cresting is another critical feature for taps, with complete coolant control along with other key grinding conditions.

Production Improvement and Cost Savings

The ability to control coolant pressure is one of the TapX’s key features, enabling high-accuracy tap production in a single setup. For fluting and thread roughing cycles, high pressure keeps the grind point cool and free of burn and swarf, ensuring optimum cycle time.

For finishing cycles, precision takes precedence over cycle time. By controlling feed rate, wheel speeds, and coolant pressure for each pass, vibration and flexion are reduced, improving the quality of the finished tap. Using VFD technology, pumps run more efficiently, as pump speed is controlled to match the required energy rather than simply switching on or off. Reducing pump speed significantly cuts energy consumption, leading to up to 20% energy savings per tool.

Example of Cost Savings

Consider a basic tap production on a coolant system with a 7kW pump, taking 20 minutes, with 80% of the time spent on threading and some cresting. By reducing the pump speed by half for finishing passes (25% of the time), the coolant pump uses 90% less energy compared to full speed. This can reduce overall energy usage for the tool by up to 20%, translating into substantial cost savings.

Product Benefits & Features of VFD Variable Coolant Control

- Provides variable coolant flow control for set operations on TapX machines.

- iTap includes variable coolant control settings for key operations.

- Improves the finish of critical tap features by reducing variations caused by high-pressure coolant.

- Offers energy-efficient production, offsetting any pump upgrade costs.

- High-pressure coolant pumps are often the highest energy consumers in the tool production system. Reducing pump cycles and using only the necessary pressure increases efficiency and reduces costs per tool.

We suggest you speak with your local ANCA representative about applying VFD coolant control to your TapX today to realize the benefits of this cost-effective feature.