In the ever-evolving world of advanced manufacturing, GROB stands at the forefront with its cutting-edge automation solutions and machining technologies. From flexible pallet systems over robotic cells to mobile robots, GROB’s innovations are reshaping how industries approach production e#iciency, flexibility, and quality.

Pallet System Change: Enhancing Flexibility and Throughput

GROB’s pallet systems are designed to maximize machine uptime and streamline production workflows. GROB o#ers a range of pallet storage solutions, including rotary, linear, and tower systems. These systems allow for parallel loading and unloading of workpieces, enabling continuous machining and reducing idle time.

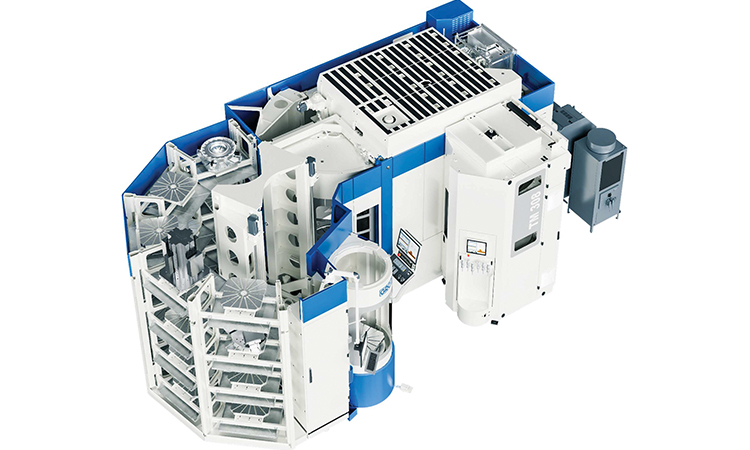

The recently introduced new PSS-R900 rotary pallet storage system represents a significant advancement in modern manufacturing. Designed to deliver more pallet capacity, greater flexibility, and extended runtime, the system is engineered to enhance productivity and operational e#iciency across production environments.

It supports continuous production by combining intelligent job planning with ergonomic machine operation, e#ectively minimizing downtimes. The system’s design enables maximum productivity by increasing output and optimizing the use of machine capacities. At the same time, it contributes to cost e#iciency by lowering unit costs through higher levels of automation and improved process stability.

A key strength of the PSS-R900 lies in its flexible configuration options. Customers can choose to integrate either one or two machining centers, allowing them to tailor the system to their specific production needs. The storage layout can also be customized, with or without pallet tower storage (PTS), depending on the requirements of the production environment. Additionally, the system o#ers a variable pallet capacity ranging from 15 to 32 pallet spaces, making it adaptable to a wide range of operational demands.

What truly distinguishes GROB is its ability to deliver a complete manufacturing solution from a single source. Not only does GROB provide advanced 4- and 5-axis machining centers and automation systems, but it also develops its own software in-house.

GROB4Automation: The Digital Backbone

At the heart of GROB’s automation strategy is the GROB4Automation software suite, part of the broader GROB-NET4Industry platform. GROB4Automation is the process control system, which significantly enhances the e#iciency and performance of GROB’s automation solutions. This intuitive and clearly structured software enables operators to easily configure, plan, and monitor production jobs. Designed to meet a wide range of requirements while o#ering an excellent price-performance ratio, GROB4Automation is highly customizable with numerous options

Two additional technical innovations released this year are the Vario rotary table for the G550 and the hydraulic clamping concept for the mill-turn machines.

Aerospace: Maximum flexibility with the new Vario rotary table for the G550

The newly introduced bigger Vario rotary table is a specialized solution designed for machining turbine components as well as thin and slender parts. With this development, GROB is setting new benchmarks in the production of turbine blades of all types. Thanks to its modular design, customers can configure the system to their specific needs – from a basic module to two highly dynamic, directly driven B-axes. These independently controlled B-axes are equipped with specialized drive configurations that help relieve stress during roughing operations and prevent component distortion during finishing, resulting in even greater precision. The Vario rotary table also features a movable counter-holder axis that accommodates various component sizes up to 700 mm in blank length, allowing for flexible and e#icient processing of a wide range of parts

Standards in Milling and Turning: One Setup, Complete Machining

GROB’s universal machining centers—such as the G350T, G550T, and G750T—are designed for simultaneous 5-axis milling and turning in a single setup. This capability not only saves time and floor space but also enhances part accuracy by eliminating multiple clamping operations.

GROB has introduced a new mill-turn machine equipped with a hydraulic clamping system. This solution is ideal for companies seeking e#icient production of milled and turned parts in medium to large batch sizes. The intelligent sensor technology, which ensures maximum process reliability, is particularly noteworthy. This makes production processes even more reliable and user-friendly. Another advantage is the permanent clamping pressure, which is also maintained during turning operations. This leads to consistently high precision and reduces the risk of clamping errors or material deformation.

For more information,

www.grobgroup.com