ANCA’s new CIM3D V9 release of the industry-leading CIMulator 3D software has an upgraded interface with fresh colours and icons and is even easier to use with intuitive functionality. The latest technology and software design has been packed into this release offering time-saving benefits and interactive visualisation across the entire grinding process.

Thomson Mathew, ANCA Software Product Manager says: “This upgrade responds directly to what our customers want and need for effective tool simulation. CIM3D V9 allows for customisation based on regularly-used features no matter which industry. The simulation quality of ANCA’s software is unmatched and you can simulate complete grinding sequences.”

“The offline capabilities of using the latest CIM3D version mean important background calculations are easily verified, increasing machine productivity. This not only maximises machine time but for those working from home, CIM3D can be run independently on any computer – so it is possible to do all the programming remotely.”

“We have automated many manual steps and introduced process verification and analysis in a central hub to get improved cycle time, and better wheel and tool life. Collisions can be detected automatically and overall CIM3D V9 is more enjoyable and easier to use.”

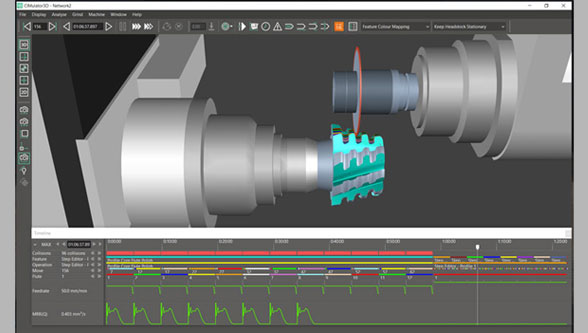

The new software offers clearer visualisation with the customisable timeline panel – effectively a central dashboard for quicker and easier tool analysis. New tool programs can be verified for size, shape, machine clearance, cycle time estimates, and more.

Chris Wagner, Tool Grind Lead at Acutec Precision Aerospace, Inc. in the U.S has been using CIM3D for 20 years and can’t imagine going back to an earlier version after trialling the latest release. He said: “CIM3D V9 is worth its weight in gold. The new look and feel is current and clean. One of the best features is progressive grinding – it gives the ability to see the exact material being removed as the wheel moves through.”

“The resolution of the graphics is far better than any previous version. Determining protrusion length, cycle time estimation, using the scroll function on a mouse to increment the position, magnification and cross-hair positioning are other great features that make using CIM3D V9 more efficient and productive.”

ANCA’s software experts are in-house ensuring the features of CIM3D are responsive, user-friendly and tailored to the cutting tool industry.

The new features save time while simulating the programmed tool path exactly as it would be ground on the machine

UPDATED LOOK AND FEEL

• Brand new interface with new icons and colour scheme

• Better user experience and a modern look

• Customisable toolbars

• The animation toolbar has been replaced with a timeline

BENEFITS: Ease of use, improved visualisation and highly intuitive design

PROGRESSIVE MATERIAL REMOVAL

• Provides a realistic and unique view of the material removal process

• Allows visualisation of the grinding process during a move

• Allows the visualisation of the wheel imprint at any point of time

• Allows better visualisation of unexpected deviations in the wheel path

BENEFITS: Allows the user to view the state of the tool at any point of the grinding timeline

CLEAR VISUALISATION WITH THE TIMELINE PANEL

• Provides an interactive timeline of the grinding process that acts as an animation and analysis hub

• Acts as a central dashboard for all analysis rather than having it distributed in multiple places

BENEFTIS: Central analysis hub for quick and easy access to save time

TOOL BALANCE ANALYSIS

• Provides complete information about the balance of a rotating tool

• The output includes the quality grade and imbalance of the tool

• This information is then passed on to ToolRoom to balance the tool effectively

BENEFITS: Ability to manufacture high performance cutting tools

SAVE TIME WITH BACKGROUND CALCULATIONS

Simplifies workflow by doing calculations in the background rather than having users kick this off. This saves time and the automatic display doesn’t allow for errors that are accidentally missed. Some of the tasks calculated automatically without needing to be initiated by users are:

• Collisions – these are recalculated automatically when machine configuration is changed

• Material removal rates – calculated when row is shown in timeline to display the MMR graph

• Tool balancing – Tool balancing is calculated automatically when tool balancing dialogue is show

BENEFITS: Simplifies workflow, saves time, less likely to miss collisions and reduced waiting time

MATERIAL REMOVAL RATE

• Provides visualisation of the material removal rate (Q) value to visualise jump in feedrates and is useful to normalise feedrates

• A chart is provided to visualise the material removal rate (Q)

BENEFTIS: MRR can be used to optimise the feedrates for better wheel life and stable process

MEASUREMENT CAPABILITIES

• Allows the placing of three points to measure a radius

• Behaves like a 2D overlay – moves with the tool in translation, but not in rotation

• Handles the same use case as a shadowgraph

• Typically used to measure the cutting profile radii

BENEFITS: Quick and easy measurement methods to save time

CHANGES TO THE SECTIONING PLANE DIALOGUE

• Multi-step sectioning plane orientations can now be viewed in the measurement view

• Basic and Advanced dialogues merged into a single dialogue

BENEFITS: Flexibility to measure any geometry on the cutting tools in any plane

MACHINE MODELS AND ACCESSORIES

• The ‘wheel changer’ tab has been renamed to ‘wheel and coolant’

• Option for MX splash guard for better collision analysis

• FX5 Wheel Changer added to detect collisions with changer gripper

• MX and TX machine models have been updated to use the current colour scheme (as per V8 updates)

BENEFITS: Additional accessories for improved collision detection analysis

ANCA website: www.anca.com