Customers have been asking for a new carbide grade to machine Titanium 6Al4V at higher cutting speeds compared to increasing feed rates or increasing depth of cuts in that result in increased cutting forces imposed on the work piece, fixtures and machine spindles. The KCSM40 grade has an advance cobalt binder that provides exceptional thermal fatigue resistance without sacrificing the toughness customers have experienced with KC725M or X500. In addition to the new material substrate Kennametal’s proprietary AlTiN/TiN coating enhances the wear resistance at the cutting edge.

“We took the toughness of our most popular milling grades KC725M and X500 and increased the thermal crack resistance and wear resistance that will enable our customers to machine at higher cutting speeds without sacrificing toughness”

– says Scott Etling, Director of Global Product Management, for Indexable Milling at Kennametal.

The target cutting speed for KCSM40 in Ti6Al4V was 175 SFM (53 m/min) while achieving a greater than 20 cubic inches per minute (327 cm^3/min) metal removal rate for 60 minutes. Not only has KCSM40 achieved this but has results milling titanium at speeds up to 270 SFM (85 m/min) at a lower radial depth of cut. Etling says the radial engagement of the milling cutter to the work piece is one key component when optimizing the cutting speed. “At higher radial engagements, the insert is cutting the material for longer time which creates more heat at the cutting zone. The heat will not go into the titanium chips like when milling steels so controlling the heat is critical. Lower cutter speeds at higher radial engagements is a good practice. At lower radial engagements, higher cutting speeds can be achieved.”

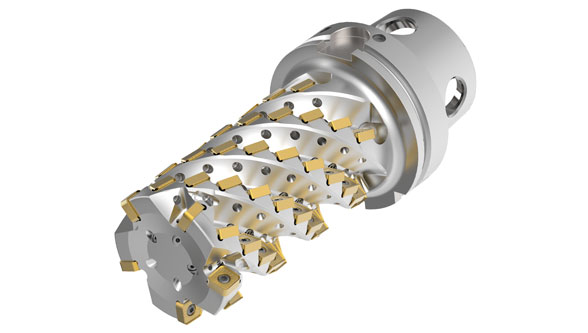

Recent internal testing with the new HARVI Ultra helical milling platform achieved over 100 minutes of tool life running at 155 SFM (47 m/min) with a .0067 ipt (.12 mm/t) chip load. The radial depth of cut was 1.0“ (25 mm) and the axial depth of cut was 3” (76 mm). Etling stated “The edge condition on the KCSM40 grade still looked great. And we are getting many other fantastic results. In one face milling operation on a hardened steel wear plate the number of passes was reduced from 234 to just 22. Needless to say I am very excited for Kennametal and the value KCSM40 will bring to our customers”.

The development of KCSM40 was indeed targeting Ti6Al4V but it will be a top performer in other high temperature / heat resistant materials. The KCSM40 is a perfect grade that aligns well with Kennametal’s market segments like Aerospace (aero structure and engine components), Energy (Turbine blades and parts made from duplex stainless steels) and Transportation (turbo chargers). Etling concluded “We continue to get test results in daily on a wide array of workpiece materials and different components delivering some very nice cost savings for our customer.”

About Kennametal

At the forefront of advanced materials innovation for more than 75 years, Kennametal Inc. is a global industrial technology leader delivering productivity to customers through materials science, tooling and wear-resistant solutions. Customers across aerospace, earthworks, energy, general engineering and transportation turn to Kennametal to help them manufacture with precision and efficiency. Every day approximately 11,000 employees are helping customers in more than 60 countries stay competitive. Kennametal generated nearly $2.1 billion in revenues in fiscal 2017. Learn more at www.kennametal.com.

![]()