Electrical Discharge Machining (EDM) has long been a staple in precision manufacturing, enabling the production of intricate and complex parts that traditional machining methods struggle to achieve. With the advent of Computer Numerical Control (CNC) technology, EDM machines have undergone a significant transformation, making them more efficient, precise, and versatile. This article explores the latest innovations in CNC EDM machines and how they are shaping the future of manufacturing.

Intelligent Adaptive Control

One of the most significant advancements in CNC EDM technology is the integration of intelligent adaptive control systems. These systems use artificial intelligence (AI) and machine learning algorithms to monitor and adjust machining parameters in real time. By analyzing factors such as spark intensity, electrode wear, and workpiece material properties, adaptive control ensures optimal machining conditions, reducing cycle times and improving surface finish quality.

High-Speed and Ultra-Fine Finishing

Recent developments in CNC EDM technology have led to machines capable of high-speed machining while maintaining ultra-fine surface finishes. Innovations such as advanced pulse power supply systems and high-frequency servo control have significantly enhanced machining speed without compromising precision. These advancements are particularly beneficial for industries like aerospace and medical device manufacturing, where high precision is paramount.

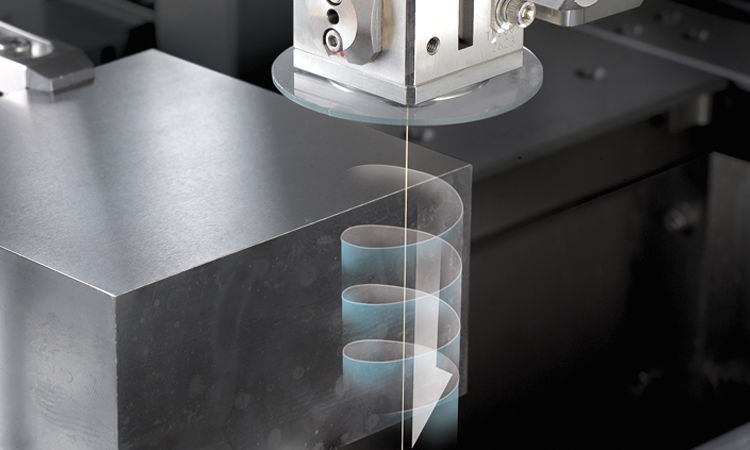

5-Axis CNC EDM Machines

Traditional EDM machines typically operate in three axes (X, Y, and Z). However, the introduction of 5-axis CNC EDM machines has revolutionized the industry by enabling complex geometries and multi-angle machining in a single setup. This innovation reduces setup times, increases machining efficiency, and allows for greater design flexibility, particularly in mold and die manufacturing.

Hybrid EDM Machines

Hybrid EDM machines combine EDM technology with other machining processes, such as milling and grinding, in a single unit. This integration eliminates the need for secondary operations, reducing production time and costs. Additionally, hybrid machines enable manufacturers to leverage the strengths of multiple machining techniques, leading to improved overall efficiency & part quality.

Automation and Robotics Integration

The integration of automation and robotics in CNC EDM machines has significantly enhanced productivity and consistency. Advanced EDM systems now feature automated tool changers, robotic workpiece handling, and real-time process monitoring. These capabilities enable lights-out manufacturing, where machines operate autonomously with minimal human intervention, improving throughput and reducing labor costs.

Dielectric Fluid Innovations

The role of dielectric fluids in EDM machining is crucial, as they facilitate spark erosion and cooling. Recent innovations in dielectric fluid technology focus on eco-friendly, biodegradable fluids that offer superior cooling and flushing capabilities. These advancements not only improve machining efficiency but also reduce the environmental impact of EDM operations.

Internet of Things (IoT) and Industry 4.0 Integration

CNC EDM machines are increasingly becoming part of the Industry 4.0 revolution, incorporating IoT capabilities for enhanced connectivity and data-driven decision-making. Real-time data collection, remote monitoring, and predictive maintenance are now possible, enabling manufacturers to optimize machine utilization, reduce downtime, and improve overall productivity.

Electrode Material and Coating Advancements

The performance of EDM machining is heavily influenced by the electrode material. Innovations in electrode materials and coatings, such as nano-coated graphite and composite electrodes, have extended tool life and improved machining efficiency. These advancements allow for finer detailing and reduced electrode wear, making EDM a more cost-effective process.

Micro-EDM for Precision Manufacturing

Micro-EDM technology has seen remarkable progress in recent years, allowing for the fabrication of extremely small and intricate components with micron-level accuracy. This innovation is particularly useful in industries such as medical device manufacturing, microelectronics, and aerospace, where miniaturization is a critical requirement.

Energy-Efficient EDM Machines

As sustainability becomes a priority in manufacturing, energy-efficient EDM machines are gaining traction. Advances in power supply technology, optimized spark generation, and energy recovery systems have led to significant reductions in power consumption without compromising performance. These energy-efficient systems contribute to lower operational costs and a reduced carbon footprint.

Conclusion

CNC EDM machines have evolved significantly, with innovations ranging from adaptive control and high-speed finishing to automation and IoT integration. These advancements are driving greater precision, efficiency, and sustainability in manufacturing. As EDM technology continues to progress, manufacturers can expect even more cutting-edge developments that will further enhance productivity and open new possibilities for complex machining applications.