High speed data capture technique cuts calibration time 85-95 percent, minimising downtime on key assets

The word “laser” implies “light speed” for the casual listener, but witnessing a bi-directional laser calibration run on just one linear axis of a CNC mill conjures up a completely different image – that of something less than the speed of light. A short 1 m axis can typically take 30 to 60 minutes as the machine axis moves in 10 mm increments and stops to pause and settle before the laser interferometer takes a reading. That pause can be as long as 23 seconds during some tests. The downtime it causes for calibration of a large, high value asset can make a machine shop owner bite through nails. Depending on machine crashes and the quality system the shop adheres to, a machine may be out of action for several days each year to perform a laser calibration, so shop owners are always focused on this issue.

New technique reduces settling time significantly

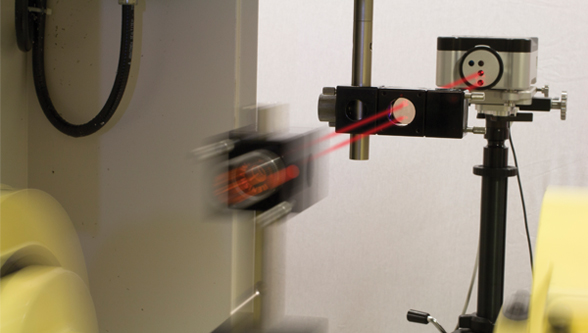

However, a technique that takes advantage of a feature in Renishaw’s XL-80 laser interferometer reduces settling time to just 250 milliseconds after each incremental axis move, cutting calibration times by 85-95 percent. In addition to reducing downtime on critical production assets, this methodology better reflects axis positioning accuracy under actual cutting conditions, where moves are fast and there is virtually no settling time before tool engagement with the work.

Quality Tech Services in Byron, Georgia, USA, has used the technique and instructed new laser buyers on it as well. “As a new calibration service, the first concern we hear when we walk in the door is downtime on a machine,” said Mike Schraufnagel, company owner. “Customers will do anything to cut downtime on a critical asset, and our customers who own lasers love this capability. For us, the technique has been a boon to our efficiency. What normally would take 30 minutes now takes just three. In one afternoon we were able to complete six laser set ups and three ballbar set ups on a machine in two hours. This would normally have taken at least a day.”

M-Code and an open contact relay is all that is required

To use the high speed calibration technique, a machine’s CNC could use an available M-code which, if not available, is usually a purchasable option to close a “normally open” set of relay contacts for between 10 and 20 milliseconds. Closure of the relay contacts, via an auxiliary I/O cable, will provide a trigger for the laser to record the difference between the laser reading and the target position. M-codes are typically used in CNC for probing cycles, to control coolant and capabilities other than axis positioning moves, so this option is available as standard on many CNC. In others M-Code may be an option that simply needs to be purchased or turned on by the OEM.

“We identified spare relays that can be controlled via M-Codes on a Haas CNC machine in our lab. This got us started in thinking of the many ways users could reduce overall machine down time by triggering the laser interferometer via a part program. This type of signalling will more accurately record the moment the machine achieves its commanded position” said Michael Wilm, Calibration Business Manager, Renishaw Inc. “Because mechanical relay contacts can bounce for the first few milliseconds, we have added a bounce rejection feature programmed into the electronics of the laser. The laser simply needs to see the relay close for as little as a microsecond; any chatter within 20 milliseconds gets ignored, the laser takes a reading, and the axis moves to the next measuring position.”

High speed data capture can be used to calibrate positioning stages and other equipment where no CNC is involved. “It may take some customising of the machine control with an auxiliary board to trigger the laser, but these boards are readily available and well known by people in the controls business,” Wilm concluded.

![]()