When faced with the choice to continue outsourcing dished heads for your tank and pressure vessel production or to start making them inhouse, it is of utmost importance to decide beforehand the ideal process technology, that is the correct balance between the manufacturing costs, production time, tooling costs and energy consumption.

In principle, there are two methods, cold and hot forming. For both options, there is the process line of deep-drawing and the two-step process, dishing and flanging.

The deep drawing method is the best choice for repetitive pressed heads; the tools are tuned for each size and therefore the operating costs are calculated on a serial production of heads.

Cold or hot processing is then the result of the evaluation of material type, geometrical dimensions, and cost of the equipment. Hot forming requires less force but more energy consumption in the forming process. Cold forming is normally used for LPG tank heads and similar applications of light walled tanks.

The dishing and flanging method has been used all over the world as it is a versatile process that can perform a wide range of plate quality, thickness, and diameters.

This versatile process requires a deep experience to achieve the best performances from a process line up to the extreme of the capacity range.

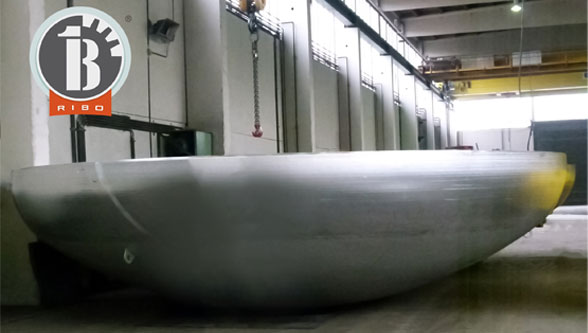

At Faccin Group, we have reached capacities still unsurpassed in the world market. We cover in cold forming, a capability of manufacturing heads from 2mm up to 80mm in material 360 Mpa and elliptical shape. In hot forming, we have reached a plate thickness 210mm for a 5000mm diameter elliptical shape being used for secondary pressure vessels of nuclear plants.

Since capacity is not limiting, it is vital to evaluate the cost efficiency of the production in terms of process time and thinning of the plate from the flat to the final head. The thinning factor is significant as the material used nowadays in the market has a higher Tensile Strength than the ones used decades ago. Thinning, understood as the reduction of thickness due to the dishing and flanging process, has a drastic impact on the mechanical properties of the vessel. High thinning will be the cause of extra cost in the material purchase and lower quality of the final product.

We have developed a unique know-how in the design of the geometry of the axis and exclusive hydraulic drives; these design achievements are the actual secret of the high efficiency of our dishing presses, manipulator, and flanging machines.

We have recently designed and manufactured a flanging machine with “without center hole” and CNC controls configuration. This machine will be able to flange Titanium heads in hot forming being very versatile in the range of possible diameters. For the same customer we are now building a new dishing press that has the possibility of cold and hot forming equipped with a special advanced hydraulic design that will cut the energy consumption up to 50% increasing the overall speed 12%.

Our policy is to assist Clients from the feasibility study up to the final run-off at their plant, including support in the equipment lay-out and training of workshop foreman and machine operators.

visit www.boldrini.com