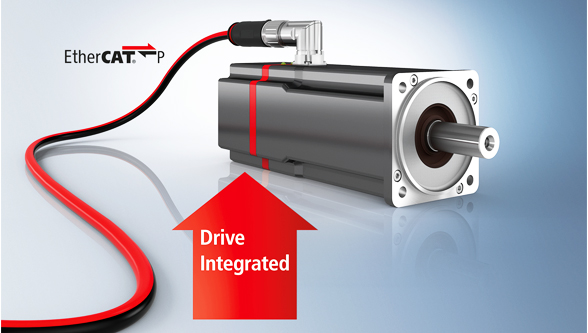

By integrating a servo drive directly into a servomotor in an ultra-compact design, AMP8000 Distributed Servo Drive system from Beckhoff offers cost and space savings

The new AMP8000 distributed Servo Drive system from Beckhoff breaks new ground for modular machine concepts. The space-saving AMP8000 integrates a servo drive directly into a servomotor in an ultra-compact design. By relocating the power electronics directly into the machine, the control cabinet only needs to house a single coupling module to supply power to multiple servo drives with a single cable via a distribution module. The result: significant savings in terms of cost, space, materials and installation effort.

With the AMP8000, space requirements for drive technology inside of control cabinets can be reduced to a single coupling module. Via EtherCAT P, providing EtherCAT signals and power with one cable, such a coupling module can control up to five distributed AMP8000 Servo Drives via an IP- 67 protected AMP8805 distribution module.Since the entire AMP8000 system is cascadable, even complex motion systems can be implemented with a remarkably simple topology.

In addition, Beckhoff offers preassembled cables that simplify logistics considerably and minimise wiring errors. With fewer and smaller cable routes to the motors, installation efforts are significantly reduced.

Optimized design for efficient drive integration

The drive integration concept of the AMP8000 features an exceptionally compact design. Since the power module is conveniently located at the back end of the motor shaft, the attachment dimensions of the new distributed servo drives are identical to those of the proven standard AM8000 series servomotors. The only dimensional change is to the overall servomotor length, which is extended by approximately 7 cm.

For the machine builder, this means that only a little additional space is needed at the motor end, and adjusting the overall motion control concept is easy without having to otherwise alter existing machine designs. The AMP8000 distributed Servo Drive system is available in flange sizes F4 and F5.

Various models are available with power ratings from 0.61 to 1.23 kW and standstill torque ratings from 2.00 to 4.8 Nm (F4) or power ratings from 1.02 to 1.78 kW and standstill torque ratings from 4.10 to 9.7 Nm (F5). STO and SS1 safety functions are integrated into the AMP8000 series by default, and a range of additional safe motion functions are in preparation.